Services

a) MEMS:

MEMS design: layout design, validation (including DRC) and optimization, starting with your ideas and delivering mask-ready CAD drawings; Mechanical analyses: linear and nonlinear structural mechanics (stress, strain), displacement, contact, modal and harmonic analysis;

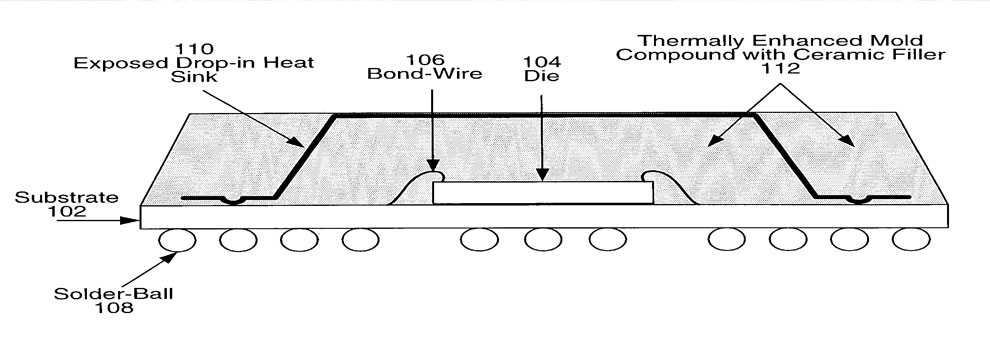

Thermal modeling: heat generation (e.g. Joule heating), thermal field effects, heat transfer (conduction, convection and radiation), thermal expansion (with results in mechanical deformation), thermal packaging issues;

mechanical deformation), thermal packaging issues;

Electrical analyses. Electrostatic modeling computes the effects of static electric fields on the MEMS device (considering or not the details of the charge distribution). Piezoelectric analysis models the effect of the stress induced when material deformation is applied. Piezoresistive simulations relates to the resistivity change subject to a mechanical deformation, providing information both on mechanical and electrical quantities;

Multi-domain modeling: coupled electro-mechanical, thermo-mechanical or thermo-electro-mechanical analyses that combine electrical, thermal and mechanical effects, providing a global, but detailed behavior of the modeled device.

Areas of application:

a) MEMS:

Capacitive accelerometers,

Pressure micro-sensors,

Resonant sensors,

Bio-sensors,

Flexible sensors.

b) Microfluidics:

General fluid flow aspects (both continuous and droplet-like flow), for computing flow problems for devices such as channels, pumps and valves, with both static and transient flows;

Multiphase flow simulations, considering the behavior of different fluids and their specific properties. This type of analyses can provide information on important phenomena, such as diffusion, mixing or switching;

Elector kinetic flow modeling, for fluids driven by electric fields, where phenomena like diffusion, convection and species migration dominate the movement. Electrophoresis, elector osmosis and dielectrophoresis can be analyzed;

Fluid-structure interaction analyses provide valuable information regarding movable or deformable structures within an internal or surrounding fluid flow;

Heat transfer modeling: heat generation (including Joule heating, like using an immersed resistor), thermal field effects, heat transfer within and outside the fluid volume (conduction, convection and radiation), thermal expansion;

Porous media, simulating the fluid’s flow through porous materials (like paper or nitrocellulose membranes) in which fluid movement is driven by capillarity.

b) Microfluidics:

Microfluid devices,

Bio-sensors,

Lab-on-a-Chip,

Inkjets,

Mixing and separation analysis