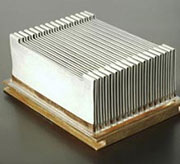

Bonded Fin & Folded Fin Heatsinks

Extruding aluminum is the most economical and widely used method of manufacturing heatsinks; however it has its limitations. That’s why at TSI we can manufacture custom Bonded Fin and Folded Fin Heatsinks.

Bonded Fin heatsinks use a stamped or pre-fabricated fin that is bonded into a channel located on a heatsink base plate using thermally conductive epoxy. Typically used in forced convection, these heatsinks can dissipate two to three times more heat than conventional extruded heatsinks by adding 200% to 300% to the cooling surface area. Fin density and height can be configured in countless combinations.

Folded Fin heatsinks use a continuous strip of aluminum or copper sheet metal affixed to an aluminum or copper base plate. The advantage of Folded Fin as opposed to extruded heatsinks is higher aspect ratios and thinner fins, thus increasing surface area and lowering thermal resistance. Fins can be manufactured as small as .006” thick. The fin stock is affixed to the base plate using either an epoxy or a brazing technique. Again, these heatsinks can be designed in numerous shapes and sizes.

TSI offers total flexibility in the design and manufacturing of our Bonded and Folded fin heatsinks. Please contact us if you have any questions. We would be happy to quote new projects or to help cost reduce an existing Bonded or Folded fin design that you may have.